- About us

- Products

- Services

- Documentation

- Contacts

English

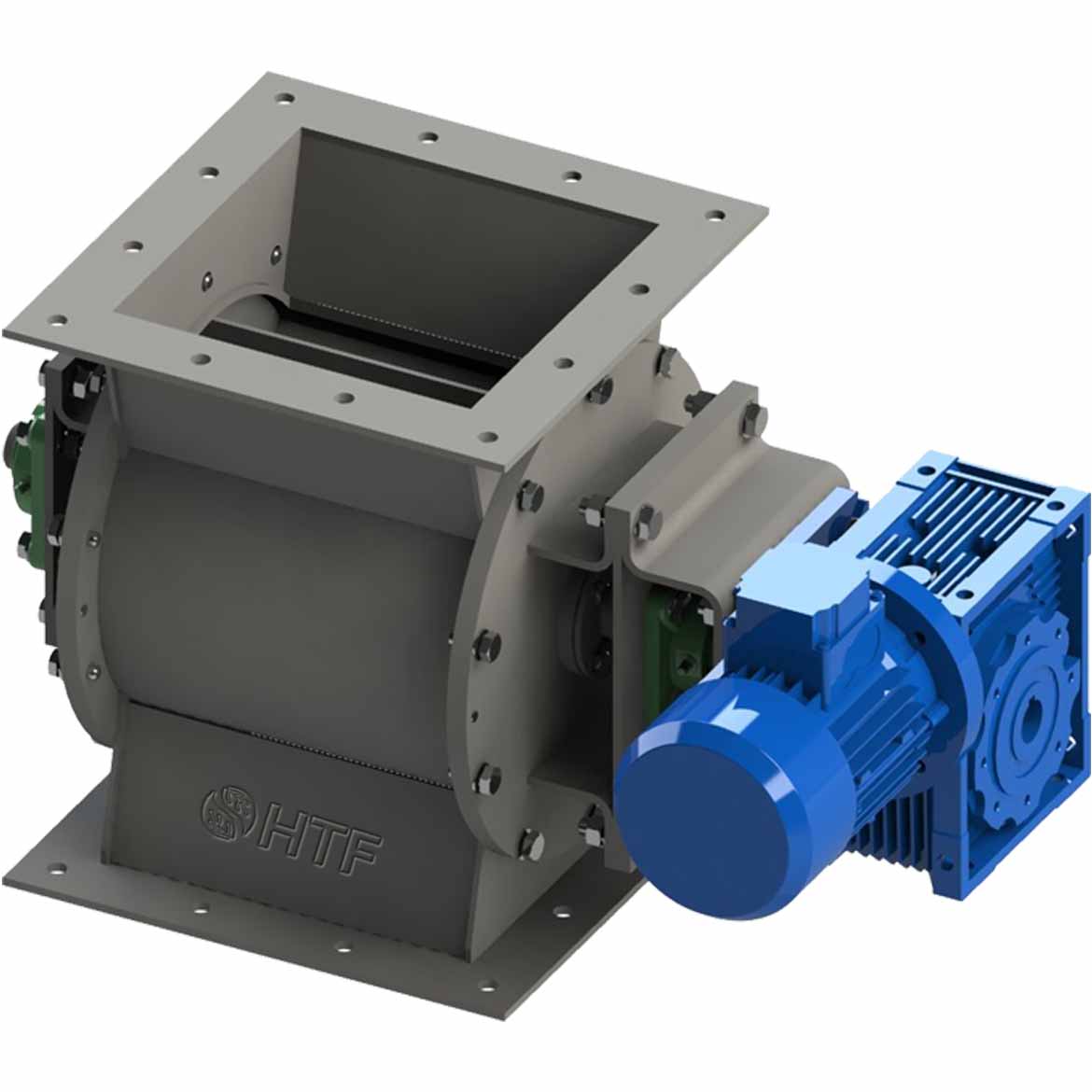

Rotary Feeders

Rotary Airlock Feeders

Purpose

Rotary feeders (valves) are designed to ensure uniform and continuous unloading/loading of dry, bulk materials (powdery, granular, small-piece, etc.) from hoppers, cyclones, silos, dust collection equipment, and pneumatic transport systems. They function as feeders (dosing units) for controlled discharge of bulk materials.Technical Specifications

- Capacity: from 2 to 40 m³/h

Manufacturing

Depending on the design, they can be used for both food-grade and non-food applications. For aspiration systems, sealing is provided to maintain the required vacuum level.Applications

- Chemical industry

- Metallurgical industry

- Food industry

- Cement industry

- Processing industry

- Glass manufacturing

Key Advantages

- Compact design

- Airtight sealing

- Easy maintenance

- Wear resistance

- Option for explosion-proof motor

- Operation in a wide temperature range

Additional Equipment & Design Options

- Body and rotor materials: carbon steel, stainless steel, or thicker steel

- Mounting options: standard drive mounting, remote mounting (chain mechanism), or without a drive

- Rotor designs: wear-resistant rotor, high-temperature rotor

- Additional rotor blade set

- Option to install an explosion-proof motor

- Custom flanges and transitions according to customer specifications

- Rotation sensor